Anders Lundmark, CEO Runway Safe: “The foam-glass product has been used as an insulating material for decades, but we’ve taken it into the next century by producing a product that has unique properties to slow down, and stop, an aircraft.”

Runway Safe has produced the world’s greenest aircraft arresting bed, made from recycled glass. Anders Lundmark, CEO Runway Safe, outlined the unique solution to Samantha Jenkins.

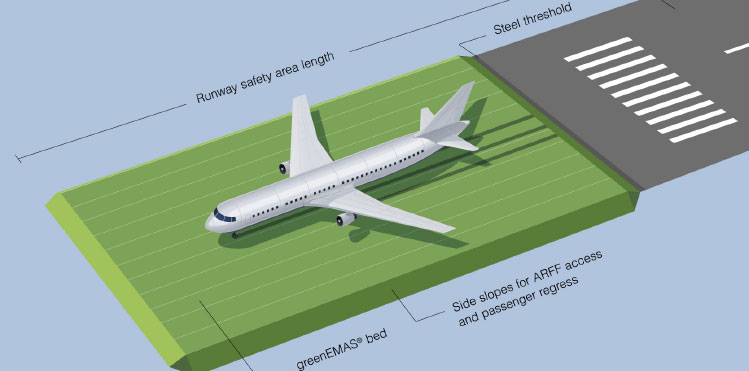

Aircraft arresting systems provide an effective overrun solution when a runway end safety area is not possible. Runway Safe is the producer of greenEMAS – the world’s first environmentally friendly, FAA-approved, runway arrestor bed.

“The active material that stops the plane in the case of an overrun is made from recycled glass,” explained Anders Lundmark, CEO Runway Safe. “In Scandinavia, we recycle approximately 96% of all glass products in special recycling stations. The foam-glass product has been used as an insulating material for decades, but we’ve taken it into the next century by producing a product that has unique properties to slow down, and stop, an aircraft.”

The first Runway Safe greenEMAS was installed in November 2014 at Chicago Midway International Airport, and is a specially designed system that uses lightweight aggregate silica foam made from recycled glass to arrest aircraft in the instance of an overrun. Foam glass is an inorganic material, which is not affected by the weather and time, resulting in a long life expectancy.

The first Runway Safe greenEMAS was installed in November 2014 at Chicago Midway International Airport, and is a specially designed system that uses lightweight aggregate silica foam made from recycled glass to arrest aircraft in the instance of an overrun.

It installed the second of four arresting beds at Midway in 2015. Lundmark explained that in one simple procedure, Runway Safe was able to replace the existing installations, and install greenEMAS. A local contractor was called in to demolish the existing bed, which was transported to the landfill. The site was then cleared for two days before foam glass was installed. A further two days were dedicated to cleaning, and then cement was poured in and cured. The final layer, known as a “rain jacket”, was applied and decorated with Chevron-stripes.

The time it takes to install greenEMAS varies depending on the customer. The first bed at Midway was installed in 56 hours, but at Zürich Airport a bed will be installed over a 40-day period during ordinary night-time closures in order to not interrupt scheduled traffic. The low installation costs and maintenance costs makes the solution suitable for small and large airports.

The construction of greenEMAS is done entirely onsite with the help of local contractors, and much of the material can be produced locally. The system is built in one piece without modules, and in the instance of an incursion, can be repaired within a couple of days. “This makes an extremely short down time of the runway in case of an incursion compared to others on the market, and this is extremely valuable for the airports,” Lundmark said.

He explained that with greenEMAS not only are lives saved in the case of an overrun, it is easy and quick to repair with spare material stored onsite. After retracting the arrested aircraft, the damaged part is cut out and loose fill foam glass is added with cover layers.

“Since the design is monolithic construction and the foam glass is an inert material, the maintenance costs are significantly lower than the competitors. So, not only is the overall lifetime cost low, we provide airports with an alternative green and sustainable solution,” he said.

Looking ahead, Runway Safe will be undertaking a further two installations of greenEMAS at Midway in 2016. It also has plans to expand its solution worldwide.